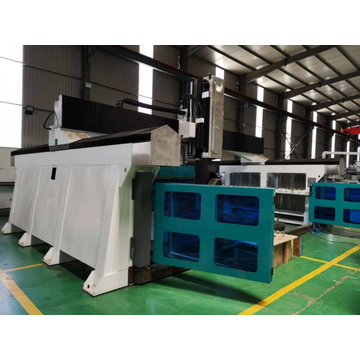

Click on the follow link to find out more information: http://www.jn-jingxun.com/foam-cnc-ruter/

Company Info

- Company Name: Jinan Jing Xun Cnc Equipment Co., Ltd

- Representative: Niancheng Jiao

- Product/Service: CNC Router , Atc CNC Router , Wood CNC Router , Laser Cutting Machine , Fiber Laser Cutting Machine , Plasma Cutter

- Capital (Million US $): US$5 Million

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 30,000-50,000 square meters

- Factory Location: Caiyuan Industrial Park, Licheng District, Jinan City, Shandong Province

- Contact Person: Mr. jiao nian cheng

- Tel: 00-86-13406418295

Email to this supplier

Premium Related Products

Other Products

Hot Products

High quality colorful stainless steel kitchen cabinetLong lift time China quality solid wood kitchen tableSample available factory directly aluminum folding door hardwareSatisfying service removable shuttersSample available combination bookcasesAdvanced Germany machines factory directly "l" shape baked-paint kitchen cabinetAustralia Style Modern Lacquer TV Stand Cabinet Furniture Design for SaleAustralia Style Modern Lacquer Laundry Sink Cabinet Cupboard Design Made in China for SaleAustralia Style Modern Bake Painting Lacquer Wall Mounted Bathroom Vanity Cabinet Set with Quartz Countertop for SaleModern Bedroom Wooden Furniture Walk-in Bedroom Wardrobe Closet Made in China for Salemixed style kitchen cabinet for European marketModern Italian Design Melamine kitchen cabinetPopular PVC kitchen cabinet American StandardClassic Oak Solid Wood kitchen cabinet American StandardModern Natural Wood Veneer kitchen cabinetWhite high glossy lacquer kitchen cabinet high quality standard